AMI’s High Temperature Units are specifically designed to operate in temperatures up to 450 °F. The combination of heat stabilization, greater internal clearance, advanced silicone seals, specially selected high temperature lubricants, and zinc anodized slingers are what make these units the perfect solution that can endure operating at elevated temperatures. Available in C4HR5 (up to 400 °F) and C4HR23 (up to 450 °F).

- C4 Internal Clearance

- Silicone Seals

- Zinc Anodized Slingers

- Steel Cages

- Fixed and Float (expansion)

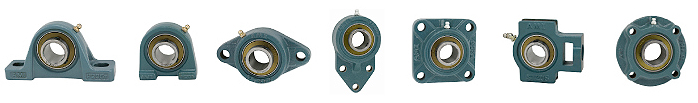

- All Housing Styles Available

Most bearing manufacturers consider lubrication to be the only difference between a standard and High-Temperature insert, however the grease is only one of the many important elements that make up a true High-Temperature insert.

INTERNAL CLEARANCE

In the manufacturing of ball bearings, it is a standard practice for AMI to assemble its rings and balls with a specified internal clearance. In the case of High-Temp inserts, internal clearance is even more important in compensating for thermal expansion of bearings, shafts and housings. AMI uses internal clearance standard of (C4) on all of our High-Temp inserts.

SILICONE RUBBER SEALS

Most standard units are supplied with a nitrile rubber seal. Nitrile rubber is an excellent seal at temperatures ranging from 0 to 212 degrees F. Soon after that temperature, nitrile rubber starts to breakdown… Leaving no sealing element to retain the High-Temp lubrication. Silicone seals have excellent temperature stability, exceptional release from sticking, resistance to aging, ozone, sunlight and outstanding water repellence. The use of silicone seals insures that the High-Temp lube stays where it belongs… in the bearing!

ZINC ANODIZED SLINGER

In order to allow the silicone to properly do its job as a seal, AMI uses a special zinc anodized slinger to protect it. The purpose of a slinger is not only to protect the seal, but also to provide the first line of defense for the balls and retainer against contaminants. Using a standard cold rolled steel slinger in a High-Temp application may initially provide protection, but quite possibly corrode and lead to premature bearing failure. AMI’s process of zinc anodization produces a slinger with two key attributes… Heat and Abrasion Resistance. A resistance that will maintain its properties well past the operating temperature of the bearings.

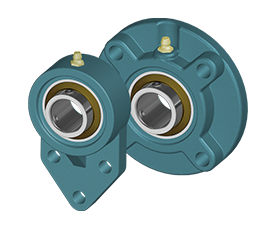

AVAILABLE IN ALL HOUSING STYLES